Lockup torque converters have been around now for some time. They came into production around the time when fuel mileage demands were put into effect by the government, and the auto manufacturers needed to do something to better connect the fluid coupling (torque converter) of the automatic transmission to the motor. By doing this, OEMs found that there were major benefits to eliminating the slip that the earlier non-lockup torque converters had, plus noticeable gains of up to 65% to 70% in fuel efficiency. Awesome! This changed the industry.

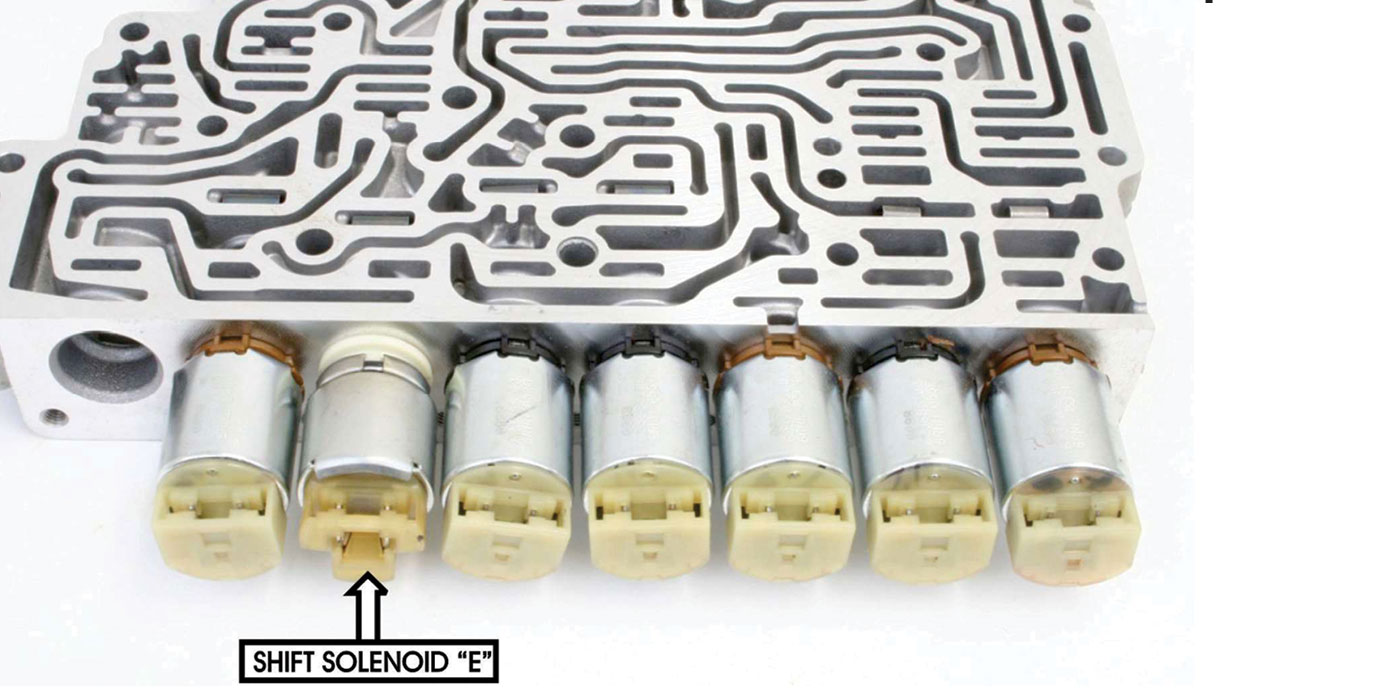

To achieve this lockup, the OEMs added a disc clutch (normally held off by release oil and converter charge) to be forced against the cover. In most cases, this is achieved by controlling the exhaust (see Figure 1, above).

By releasing the oil holding the clutch off, the charge oil is able to force the disc against the cover. This is the most common type of lockup torque converter. However, in some applications, the OE installed an actual clutch drum inside of the torque converter to be used for lockup (seen in Figure 2).

In this design, instead of releasing oil, it sends apply oil back into the converter to force the clutch pack to apply, thereby locking the input shaft to the engine rotation. The auto manufacturers, by adding either of these styles of lockup clutch setups, could maintain a lock directly to engine rotation.

The early lockup systems were no different than a light switch mounted against the wall. They were either on (locked) or off (multiplying torque). This exchange typically only happened in high gear when either in third or fourth gear. Ratios changed as technology evolved, though, and now we are dealing with six-, eight-, and 10-speed transmissions. These changes, like everything else in the automotive industry, produced great gains over time in fuel savings. Manufacturers found that they could bring the converter clutch on to a particular lock condition during lower speeds—essentially a dimmer switch—to meet government fuel economy mandates.

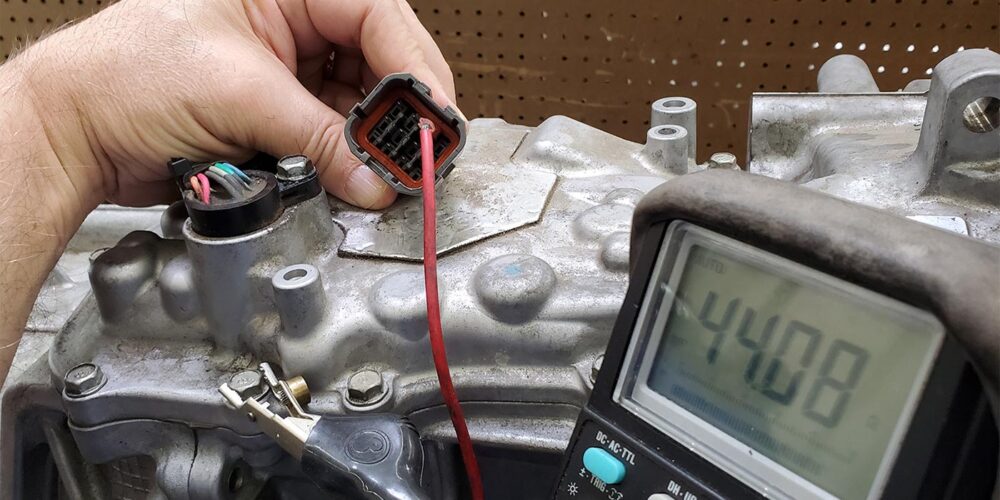

Today, OEMs are bringing on the converter clutch as early as second gear and continuously allowing for a slip of the clutch disc or drum to fine-tune the fuel management and maintain engine balance to the transmission. This brings a whole new problem in the transmission shop when dealing with converter clutch damage and engagement feel, shudders, bangs and vibrations. Often, the technicians are faced with tackling the car’s computer programs, and vehicles often need updates in programming to fix issues.

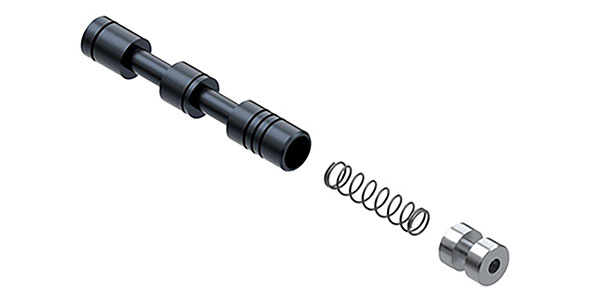

Transmission fluids have also become very specific and critical to maintain converter life. Incorrect fluids can cause low-speed chatters (since they are bringing the clutch on as early as second gear, and it doesn’t grab due to the lack of modifiers), creating more heat than can be cooled and, ultimately, clutch failures. Converter failures are filling the transmission with metal debris and causing valves in the control bodies to stick, solenoids to restrict and hard parts to fail. These are expensive repairs.

In summary, here’s the good and bad of these torque converter designs:

The positive: Gains in fuel mileage are achieved by bringing the torque converter clutch on early, such as when driving in and around town.

The negative: Because the converter is so active, transmission issues now are commonly caused by the converter and failures surrounding it.

Repair shops and customers are aware of issues caused by early lockup and often resort to what’s often called “aftermarket programming” to change the timing or the gear when lockup comes on (off-road use only) to the higher gear ranges. It is a whole new can of worms when this happens, especially if the vehicle still has a manufacturer warranty. Always investigate the legal issues before resorting to the aftermarket tuning. Just know that these changes will, in many instances, fix all the issues with torque converter timing, but it may void other warranties. Be wise when making changes.

Read more stories from our TASC Force Tips series here.

Randall Schroeder is a Sonnax technical sales and training specialist. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.